Access the safest gates around

Our self closing safety gates are spring loaded so will automatically close behind the user.

All self closing safety gates are available in galvanized steel finish or yellow powder coated.

Choose between single or double width self closing safety gates so you have the right size gate for your space.

They are quick and easy to install which saves time and money.

The width can be cut to size on-site so they can be adjusted as needed

Can fit different surfaces (round or square) and can be used for external and internal applications.

Kee Safety runs one of the world’s leading test and training centers at its UK Head Office. Run by a team of industry experts, this state-of-the-art facility ensures Kee Safety meets the needs of its customers, provides them with fully compliant products, and drives new innovation with the purpose of separating people from hazards.

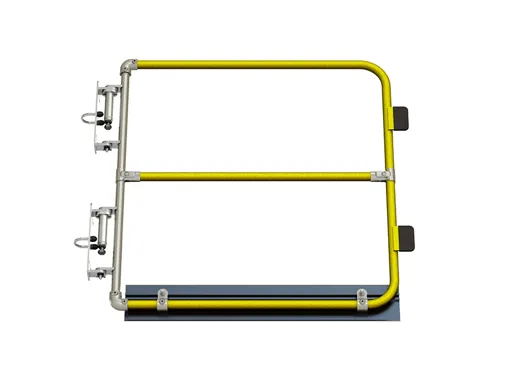

This gate is sized at 39" wide, and can be easily cut to size on site. The reversible hinges can be fitted on the left or right side of an opening, making installation easier and more flexible. The spring-loaded hinge mechanism ensures that the gate will always close, maintaining a safe barrier to protect people when working at heights.

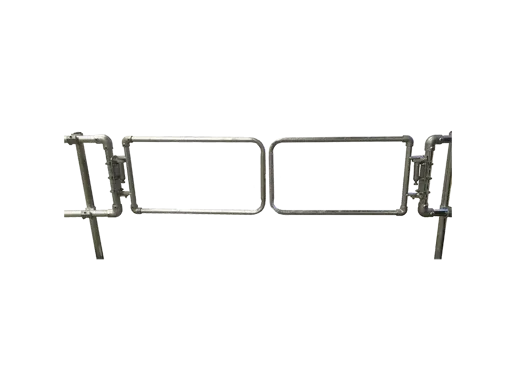

These double gates are sized at 2 x 35" wide and they can be easily cut to size on site. They work best for larger openings greater than 39" wide and the maximum width for double gates is 70". They're spring loaded to automatically close behind the user, and its high performance hinge mechanism gives it extended life.

The full height gate is designed for ladders. Standing at 43" tall and featuring an aluminum toe board, it provides additional protection to those working at any level. The full height gate is fully adjustable and can accommodate openings up to 39".

We offer full design and installation services that include a complete on-site survey. Also, we can produce comprehensive shop drawings to help you visualize the end result. With our detailed project outline, you can be confident that your project is professionally specified, and that all safety concerns and standards are addressed to your satisfaction.

Alternatively, you can specify and install KeeGuard yourself with our easy-to-follow instructions – it all starts with a call to our knowledgeable staff!

| Document | Format |

|---|---|

| Salt Spray - Hinge Mechanism | |

| Resistance to repeated opening and closing in accordance with BS6375-2 | |

| Salt Spray - BSG - Powder Coated | |

| Universal Self Closing Safety Gates Brochure | |

| Operations and maintenance manual |

| Document | Format |

|---|---|

| Salt Spray - Hinge Mechanism | |

| Resistance to repeated opening and closing in accordance with BS6375-2 | |

| Salt Spray - BSG - Powder Coated |

| Document | Format |

|---|---|

| Universal Self Closing Safety Gates Brochure | |

| Operations and maintenance manual |

Please fill in your details below and we’ll be in touch shortly.